Virtual Tour of Our Audit Report

Section 1: Factory Profile & Preliminary Verification

The first step of our on-site audit in Quanzhou (or other manufacturing hubs) is a rigorous verification of the factory’s legal and operational identity. Unlike generic "checkbox" audits, we cross-reference official government records with the physical reality on the ground.

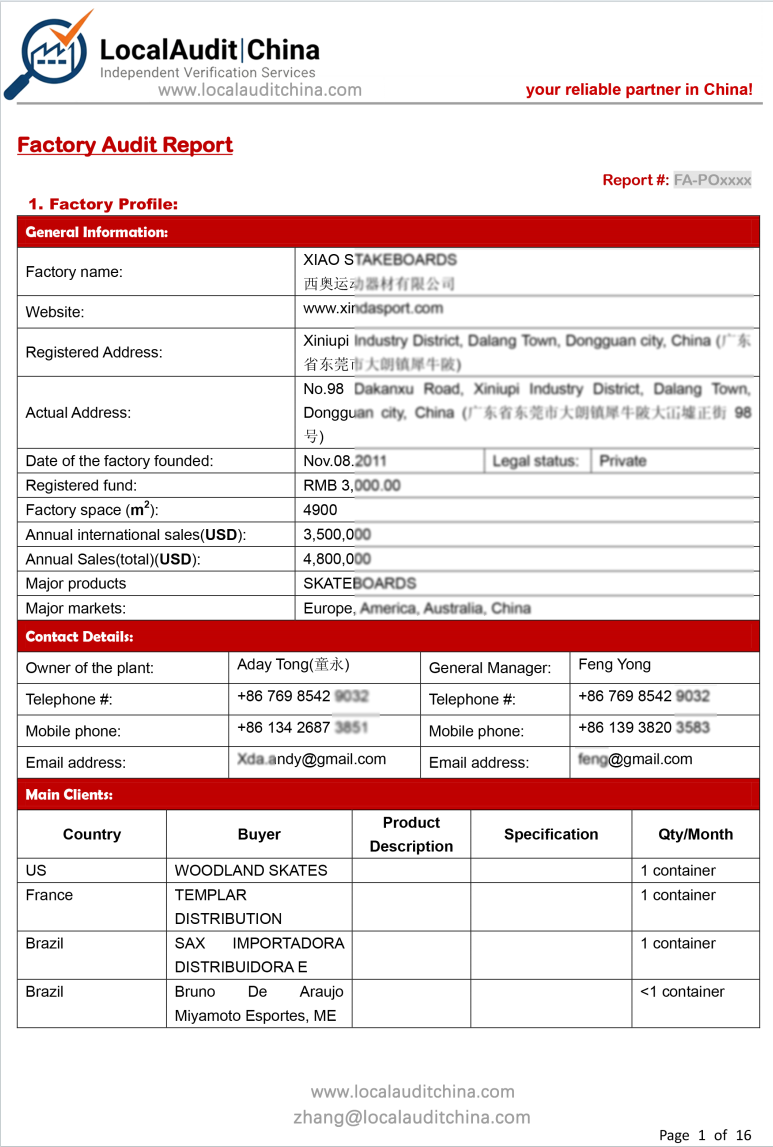

Key highlights from Page 1 of our report:

Legal & Financial Scrutiny: We verify the registered capital, founding date, and legal status to ensure you are dealing with an established entity, not a "fly-by-night" operation.

Operational Scale: We document the actual factory space and annual sales turnover to confirm the supplier has the capacity to handle your specific order volume.

Client Footprint: We analyze the factory’s current major clients and export markets. This helps determine if they are accustomed to the quality standards and compliance requirements of regions like Europe and the US.

Direct Access: We identify and verify the actual owners and key management personnel, ensuring clear lines of communication for your project.

Section 2: Organizational Structure & Real-World Production Capacity

A factory's efficiency isn't just about machines; it's about how they organize their human and technical resources. On Page 2 of our LocalAuditChina report, we dissect the factory's operational backbone.

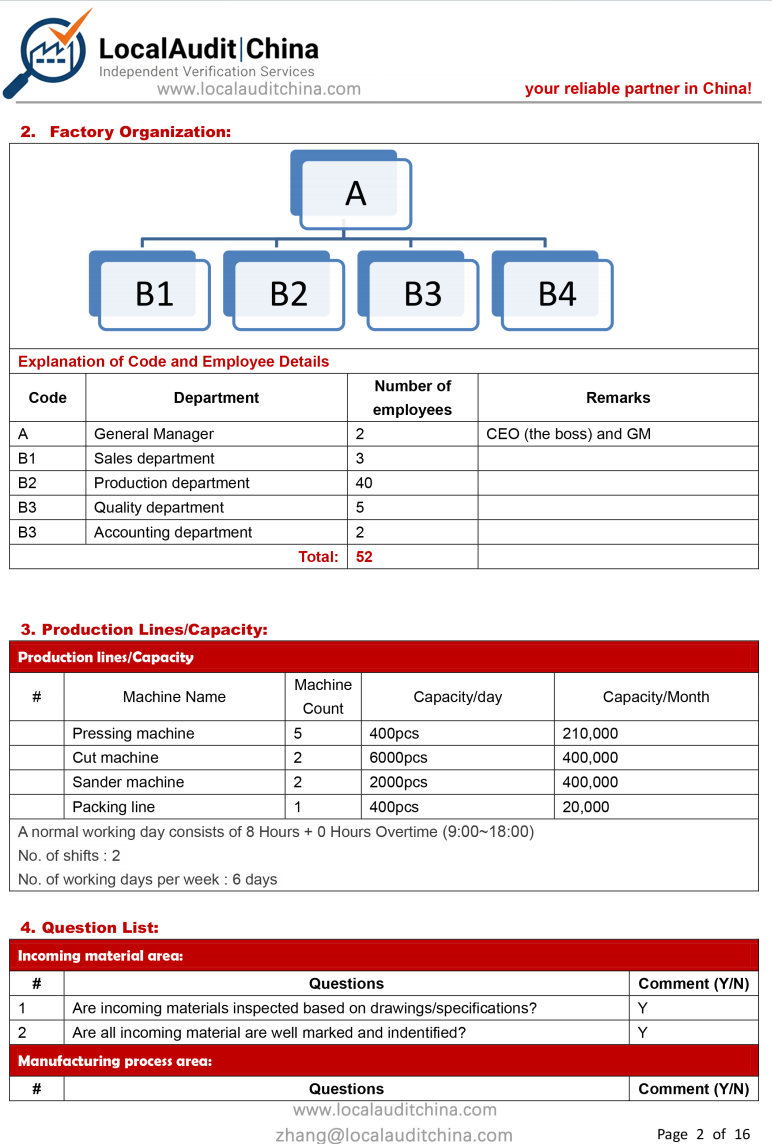

Key highlights from Page 2:

Human Resource Transparency: We map out the organizational chart to verify the balance between departments. A high ratio of production staff (e.g., 40 workers) compared to quality control (5 staff) gives us immediate insight into their QC pressure.

Verified Capacity Audit: We don't just accept "marketing numbers". We audit the actual count of machinery—from pressing and cutting to sanding—and calculate daily vs. monthly output based on a standard 8-hour shift.

Operational Rhythm: We document the shift patterns and working days (e.g., 6 days per week, 2 shifts). This allows you to calculate realistic lead times and identify if the factory is over-promising on delivery dates.

The "Question List" (Initial QC Check): We begin our on-site investigation at the Incoming Material Area. We verify if materials are inspected against drawings and if they are properly identified—crucial for preventing material mix-ups in complex projects like solar or high-end electronics.

Section 3: On-site Quality Estimation & Critical Red Flags

The difference between a "good" supplier and a "reliable" one is found in the operational details of the shop floor. On Page 3, we move beyond documentation to verify the actual Quality Culture and Order Logistics of the facility.

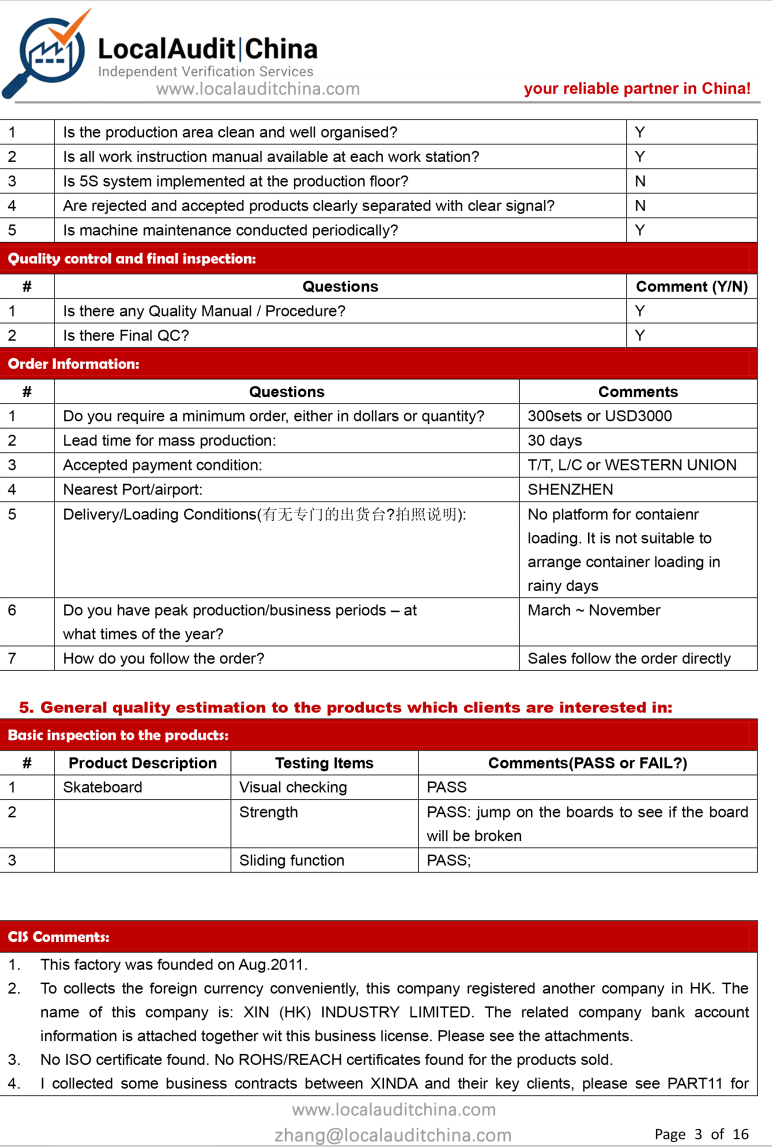

Key highlights from Page 3 of our report:

Production Environment Audit: We don't just check for cleanliness; we look for systems. While this factory maintains organized workstations, our report notes a failure to implement a 5S system and a lack of clear separation between accepted and rejected products—critical indicators of potential cross-contamination risks.

Order & Logistics Intelligence: We extract the "real" terms of business. We document the actual lead times (30 days), peak production seasons (March to November), and specific loading constraints—such as the factory's lack of a proper container loading platform, which makes rainy-day loading a significant risk to your cargo.

Physical Product Stress Testing: We perform "Basic Quality Estimations" on the spot. For this skateboard factory, our auditor didn't just look at the product; they performed a physical strength test (jumping on the boards) to verify structural integrity beyond the technical specs.

The "CIS Comments" (Professional Verdict): This is the most vital part of the page. Our auditor uncovered that the factory does not hold ISO, ROHS, or REACH certifications for the products sold—a massive compliance risk for buyers in the US and Europe that a remote agent might miss.

Section 4: Auditor Verdict & Visual Ground Truth

The conclusion of a LocalAuditChina report is where we synthesize technical data into actionable business intelligence. Page 4 provides the final "CIS Auditor" verdict and begins the photographic documentation of the facility’s exterior and entrance.

Key highlights from Page 4:

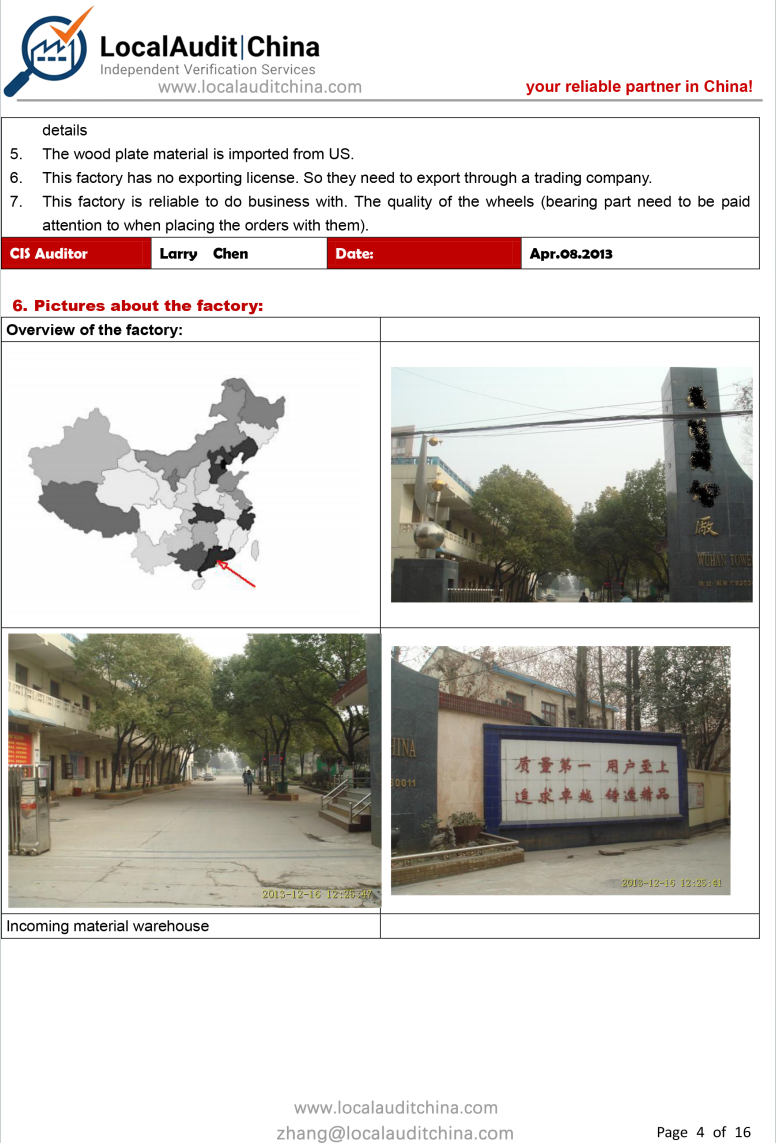

Material Origin Verification: We confirmed that the wood plate material used in production is imported from the US. This verification ensures that high-value material claims made by the factory are authentic.

Export Compliance Intelligence: Our audit revealed the factory does not possess an exporting license and must utilize a trading company for international shipments. This is vital information for buyers when structuring logistics and legal contracts.

Specific Quality Warnings: While the factory is deemed "reliable to do business with," our auditor identified a specific technical vulnerability: the quality of the wheels (bearing parts) requires focused attention during order placement.

Geographic Context: We include a customized map and exterior facility photos to confirm the factory's physical location within the industrial district.

Official Entrance Documentation: We document the factory gates and surrounding environment to ensure the scale of the facility matches the previously audited data.

Section 5: Raw Material Management & Primary Production Phases

The technical integrity of a product is determined long before assembly begins. On Page 5, our photographic evidence focuses on Material Storage and the Initial Processing stages, providing a transparent look at how the factory handles its core components.

Key highlights from Page 5:

Incoming Material Warehouse Audit: We document the storage conditions of the raw wood plates. Our auditors check for proper stacking, moisture protection, and batch identification to ensure material quality is preserved from the start.

Wood Cutting Area Inspection: We capture the primary cutting stage, where raw materials are sized for production. We observe the workflow and safety protocols in this high-dust environment to ensure operational consistency.

Board Pressing Area Verification: This is a critical structural phase. We document the machinery and manual handling involved in pressing the wood layers, looking for uniformity in the process which directly impacts the strength and durability of the final skateboard.

Direct Visual Evidence: By including these unedited "ground-truth" photos, we provide you with a window into the factory that marketing brochures never show—capturing the true state of the equipment and the working environment.

Section 6: Specialized Processing & Refinement Stages

Once the core structure is established, the product moves into specialized areas for refinement. On Page 6, our audit documents the Boards Polishing Area and advanced pressing techniques, ensuring that the final aesthetic and functional finish meets international export standards.

Key highlights from Page 6:

Boards Polishing Area Inspection: We document the mechanical polishing phase. Our auditors observe the equipment used to smooth the board surfaces, ensuring that the finish is uniform across all production units.

Advanced Pressing Equipment: We capture multiple angles of the industrial pressing machinery in operation. This documentation allows you to verify the scale and condition of the factory’s technical assets.

Workflow Observation: We monitor the movement of materials between the pressing and polishing stations. This ensures that "work-in-progress" items are handled correctly to avoid surface damage before the final coating or assembly.

Operational Safety & Environment: Our photos capture the reality of the workshop environment during peak processing. We look for adequate lighting, space for machinery operation, and general orderliness in these high-activity zones.

Section 7: Finishing, Shaping, and Painting Precision

The final aesthetics and functional safety of the product are determined during the refinement stages. On Page 7, our audit monitors the high-precision Sanding and Painting phases, where manual craftsmanship meets industrial machinery.

Key highlights from Page 7:

Manual Sanding & Edge Refinement: We document workers performing detailed edge-sanding. This manual step is vital for ensuring user safety and a premium finish, but it also introduces variability that our auditors monitor for consistency.

Precision Cutting & Shaping: We capture the use of specialized woodworking machinery used to define the final silhouette of the boards. Our focus here is on the repeatability of the cuts and the maintenance of the cutting blades.

Painting Area Environment: We inspect the painting and coating zone. Our auditors look for adequate ventilation, dust control, and the even application of primers or base coats, which are essential for long-term graphic adhesion.

Work-in-Progress (WIP) Management: We observe how boards are stacked and moved between sanding and painting. Proper handling at this stage is critical to prevent surface contamination or mechanical damage before the final finish is applied.

Section 8: Final Finishing, Assembly, and Packing Infrastructure

The final aesthetics and preparation for transit occur in specialized zones designed to ensure product readiness. On Page 8, our audit transitions into the Painting and Assembly/Packing areas, where the raw boards receive their final identity and are prepared for global distribution.

Key highlights from Page 8 of our report:

Painting & Graphic Application Booths: We document the specialized spray booths used for applying base colors and protective coatings. Our auditors check for environment cleanliness and uniform coverage to ensure high-quality graphic adhesion.

Assembly Area Workflow: We capture the final assembly zone where specialized components meet the finished decks. We monitor the organization of these stations to ensure that assembly follows a structured, repeatable process.

Drying & Storage Infrastructure: We observe the vertical racking systems used for drying finished boards. This documentation allows you to verify that the factory allows for proper curing time and organized storage to prevent surface defects before packing.

Pre-Packing Inspection Zone: Our photos show the transition to the packing line, where products are staged for final counting and boxed for export. We look for adequate space and lighting to ensure final QC checks can be performed effectively.

Section 9: Finished Goods Warehousing & Showroom Portfolio

The final audit phase involves verifying how the factory manages its completed inventory and how it presents its technical capabilities to clients. On Page 9, we inspect the Warehouse for Finished Products and the Showroom Area to ensure the transition from production to shipment is handled with professional care.

Key highlights from Page 9 of our report:

Finished Goods Warehouse Inspection: We document the storage conditions of boxed inventory. Our auditors look for organized palletization, clear labeling, and protection from environmental factors (like moisture or dust) to ensure your goods remain in pristine condition until loading.

Stock Management Observation: We capture the scale of the finished inventory staged for shipment. This provides a realistic view of the factory's current order volume and their ability to manage complex logistical requirements for multiple global clients.

Showroom & Product Portfolio Review: We document the factory's showroom, which displays the full range of their manufacturing capabilities—from raw decks to fully assembled, branded skateboards. This allows you to see the diversity of their shaping, graphic application, and assembly skills in one glance.

Privacy & Confidentiality Protocols: As shown in the "privacy" placeholder, our reports strictly adhere to confidentiality agreements. We ensure that proprietary designs or sensitive client information from other buyers are not disclosed, reflecting our high ethical standards.

Section 10: Product-Specific Inspection & Craftsmanship Details

A factory audit is only as good as the product it produces. On Page 10 of our LocalAuditChina report, we move from the infrastructure to the Physical Samples. This section provides a high-resolution look at the actual units pulled from the production line or showroom for technical evaluation.

Key highlights from Page 10:

Product Portfolio Inspection: We document a wide variety of "Product Inspected" samples. This allows you to verify the factory's versatility—ranging from raw, unpainted decks to fully graphics-applied longboards and specialized shapes.

Surface Integrity Verification: Our close-up photos capture the wood grain and surface finish of the decks. We look for uniformity in the wood layers and the absence of surface knots or cracks that could compromise structural safety.

Technical Detail Focus (Drilling & Mounting): We capture macro shots of the truck mounting holes. This ensures that the CNC or manual drilling is clean, centered, and standardized, which is vital for ease of final assembly.

Graphic Application Quality: We document the quality of the heat transfer or screen-printed graphics. Our auditors look for sharp edges, vibrant colors, and the lack of "bubbling," ensuring your brand's aesthetic is perfectly preserved.

Cross-Sectional Edge Analysis: One of the most important photos shows the side profile of the board. This allows you to count the actual layers of wood and verify the lamination quality—ensuring there are no gaps or "dry spots" between the plies.

Section 11: Business Intelligence & Official Documentation

A factory's legitimacy is proven through more than just its machines. On Page 11 of our LocalAuditChina report, we perform a deep dive into the human network and legal standing of the facility, providing you with direct contacts and verified credentials.

Key highlights from Page 11:

Macro Material Verification: We continue our close-up product inspection, providing ultra-high-resolution images of wood grain and drilling precision. This allows you to verify the ply count and hole alignment without being on-site.

Key Personnel Identification: We collect and verify the business cards of the factory’s actual decision-makers and key export contacts. Unlike a generic "sales" email, you get the direct mobile numbers, Skype IDs, and verified office addresses of the people responsible for your order.

Supply Chain Transparency: Our audit of these contacts helps verify if you are dealing with a direct factory owner or a middleman. This clarity is essential for negotiating pricing and ensuring technical accountability.

The Foundation of Trust: This page leads directly into the Business License and Company Registration section, where we translate and verify the factory's official government filings.

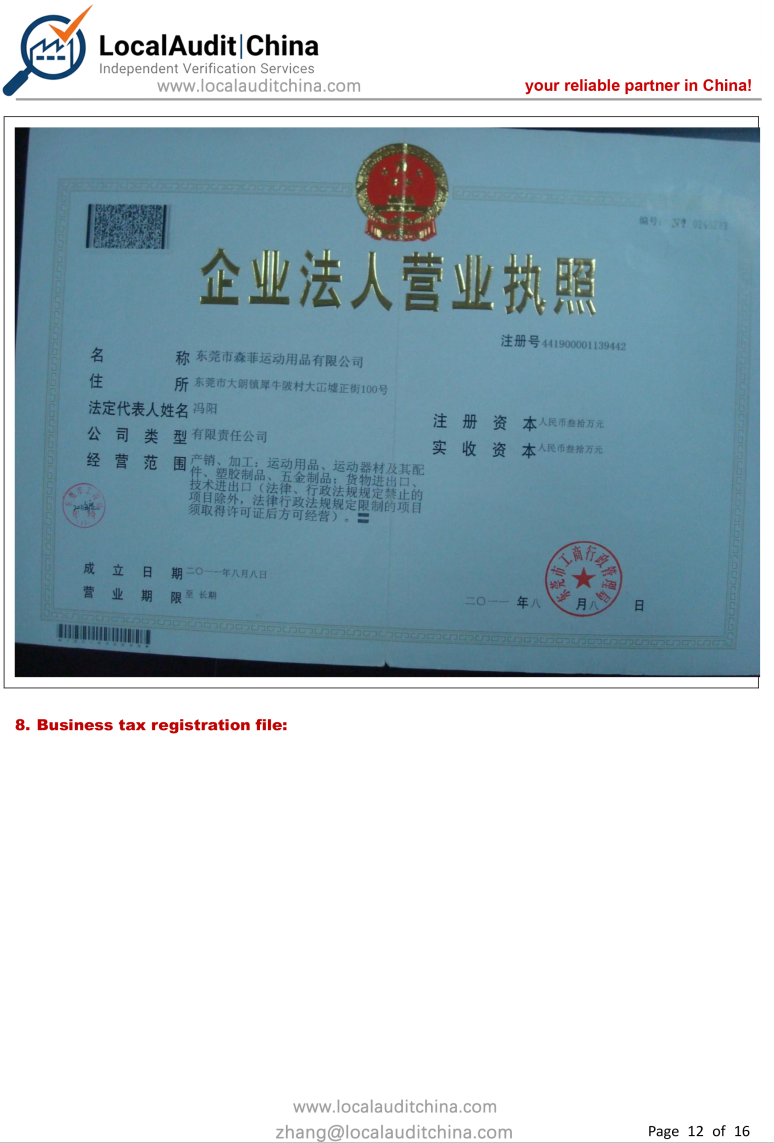

Section 12: The Foundation of Legitimacy — Business License Verification

At this stage of the audit, we move from the workshop to the legal core of the company. Page 12 of our report presents the Official Business License, which is the most critical document for any buyer looking to secure their investment in China.

What we verify on Page 12:

Legal Identity & Registration Number: We cross-check the official registration number against the National Enterprise Credit Information Publicity System to ensure the factory is in good standing.

Registered Capital vs. Reality: We verify the "Registered Capital" (as seen in the gold-embossed section) to gauge the financial scale and liability of the entity.

Authorized Business Scope: We carefully translate and analyze the "Business Scope" (经营范围). This confirms that the factory is legally permitted to produce and process the specific goods you are ordering, protecting you from future regulatory issues.

Official Seals & Validity: We check the presence of the official red stamp from the Administration for Market Regulation and verify that the license is within its valid term.

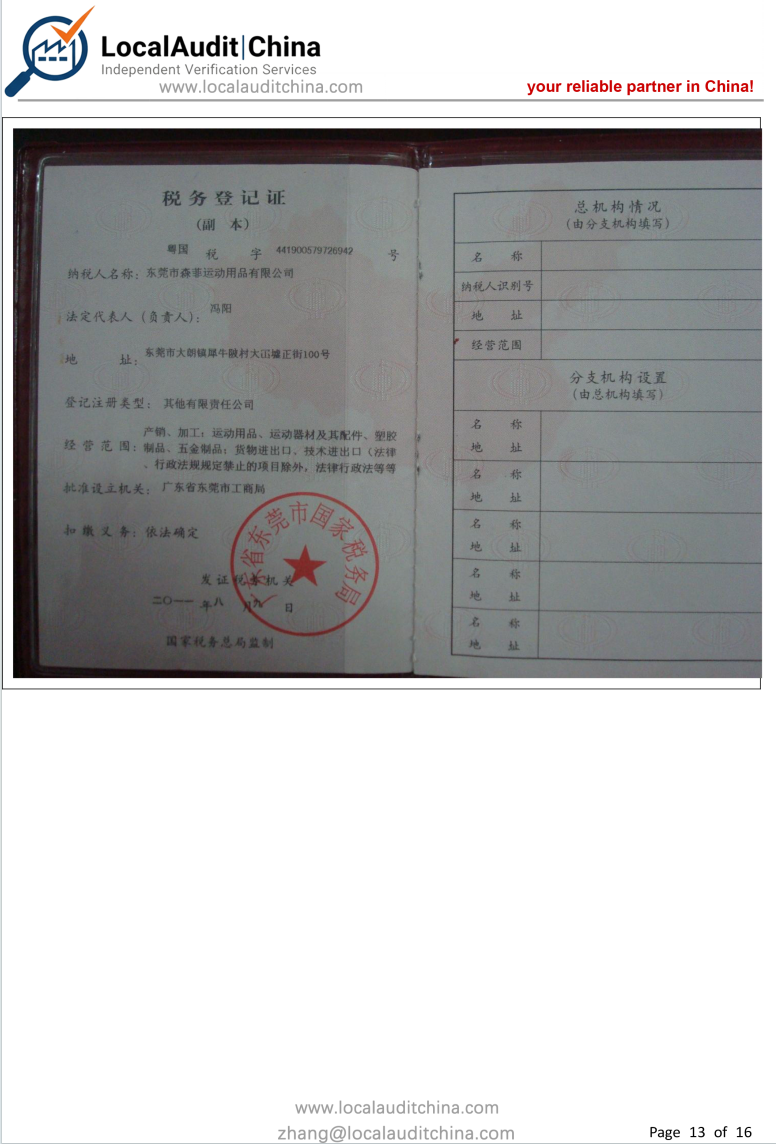

Section 13: Financial Transparency — Tax Registration Verification

To ensure our clients are dealing with a sustainable and compliant entity, we go beyond basic business licenses. Page 13 of our report features the Official Tax Registration Certificate (税务登记证) of the facility.

Why this document is vital for your security:

Governmental Accountability: This certificate proves the factory is officially registered with the State Administration of Taxation. It confirms they are a legitimate taxpayer, which is a major indicator of a stable, long-term operation.

Verified Corporate Address: We cross-match the address on the tax certificate with the physical location we audited and the address on the business license. Any discrepancy here is an immediate red flag for potential fraud.

Legal Representative Consistency: We verify that the "Legal Representative" named on the tax document matches the ownership details we identified during the on-site interview.

Anti-Fraud Shield: Dealing with an entity that has a verified tax ID reduces the risk of getting involved in "shadow" transactions or illegal subcontracting.

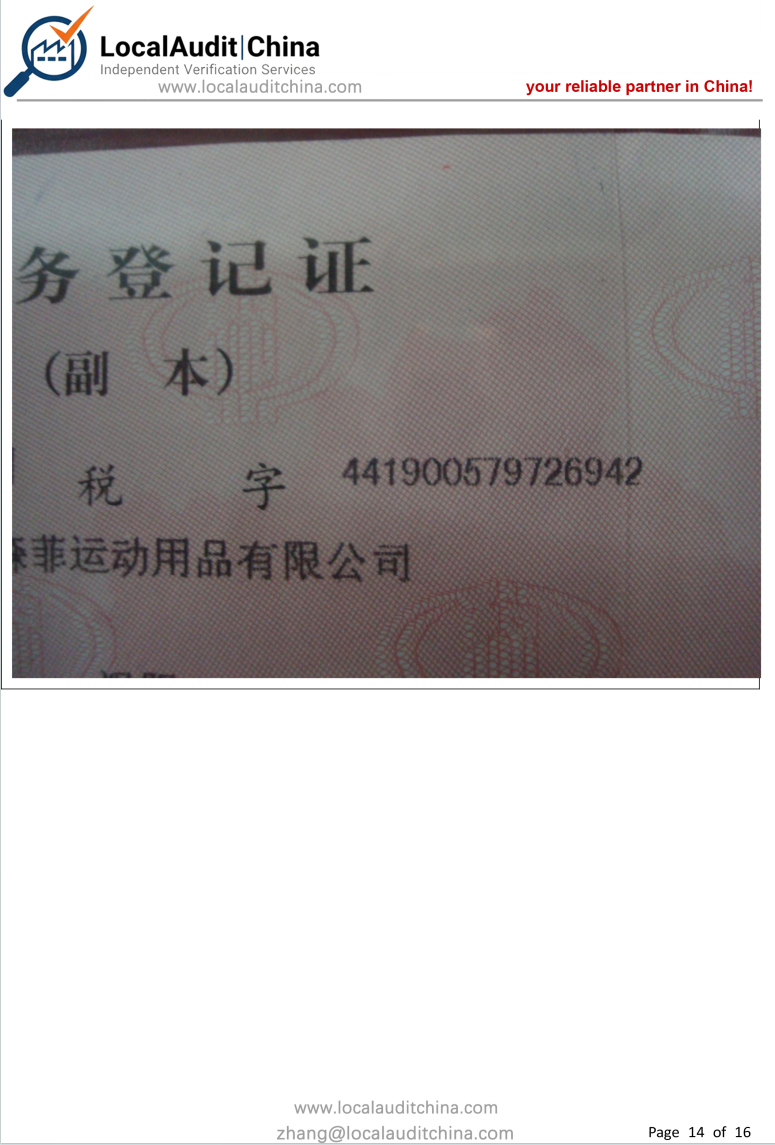

Section 14: Macro-Verification of Statutory Records

In the final stages of the legal audit, we provide high-definition close-ups of official government certificates to prevent the use of forged or digitally altered documents. Page 14 focuses on the Tax Registration Detail Verification.

Key highlights from Page 14 of our report:

Certificate Authenticity Check: We capture macro shots of the Tax Registration Certificate ( Duplicate) to verify the intricate background patterns and watermark security features.

Registration Number Cross-Matching: We explicitly document the tax registration number (441900579726942) to ensure it matches the records found on the primary business license and the official tax portal.

Entity Name Confirmation: The close-up confirms the official Chinese name of the manufacturing entity, ensuring there is no confusion between the factory and third-party trading agents.

Anti-Forgery Assurance: By providing these zoomed-in captures, we allow your legal team to verify the physical texture and official stamps of the documents, a level of detail that standard low-resolution scans cannot provide.

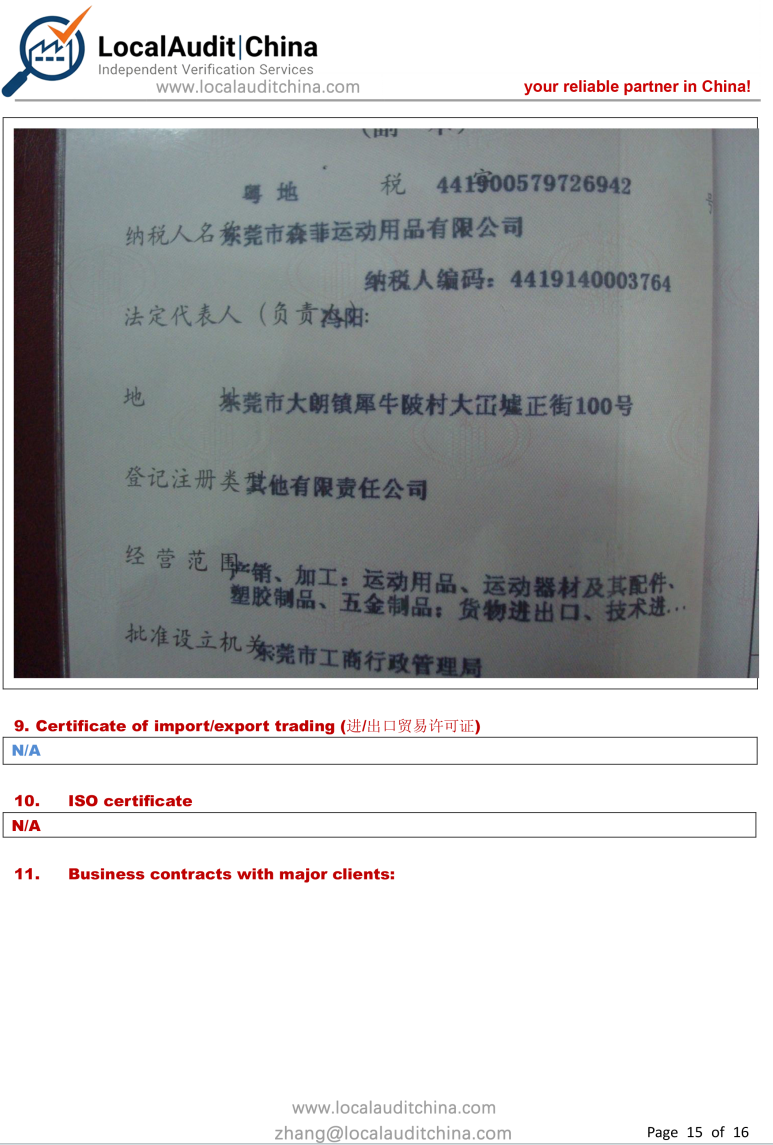

Section 15: Compliance Gap Analysis & Final Regulatory Review

The final phase of a LocalAuditChina report identifies the critical "missing links" in a factory's regulatory profile. Page 15 provides a clear summary of essential certifications and client relationship verifications, ensuring you have a 360-degree view of the supplier's professional standing.

Key highlights from Page 15 of our report:

Certificate of Import/Export Trading (进/出口贸易许可证): We explicitly verify if the factory has its own export rights. For this facility, the status is N/A, confirming our earlier finding on Page 4 that they must utilize a third-party trading company for international shipments.

ISO Certification Audit: We check for internationally recognized quality management systems. The N/A status here confirms the absence of ISO 9001 or similar standards, highlighting a potential area for quality management oversight.

Business Contracts with Major Clients: We cross-reference the client claims made on Page 1 by looking for physical evidence of past business contracts. This section validates whether the factory is truly accustomed to the quality demands of the US, European, and Australian markets.

Documentary Continuity: The page includes final macro-captures of the Business Tax Registration, verifying the local registration number (4419140003764) and the legal representative.

Section 16: Transactional Proof & Final Audit Conclusion

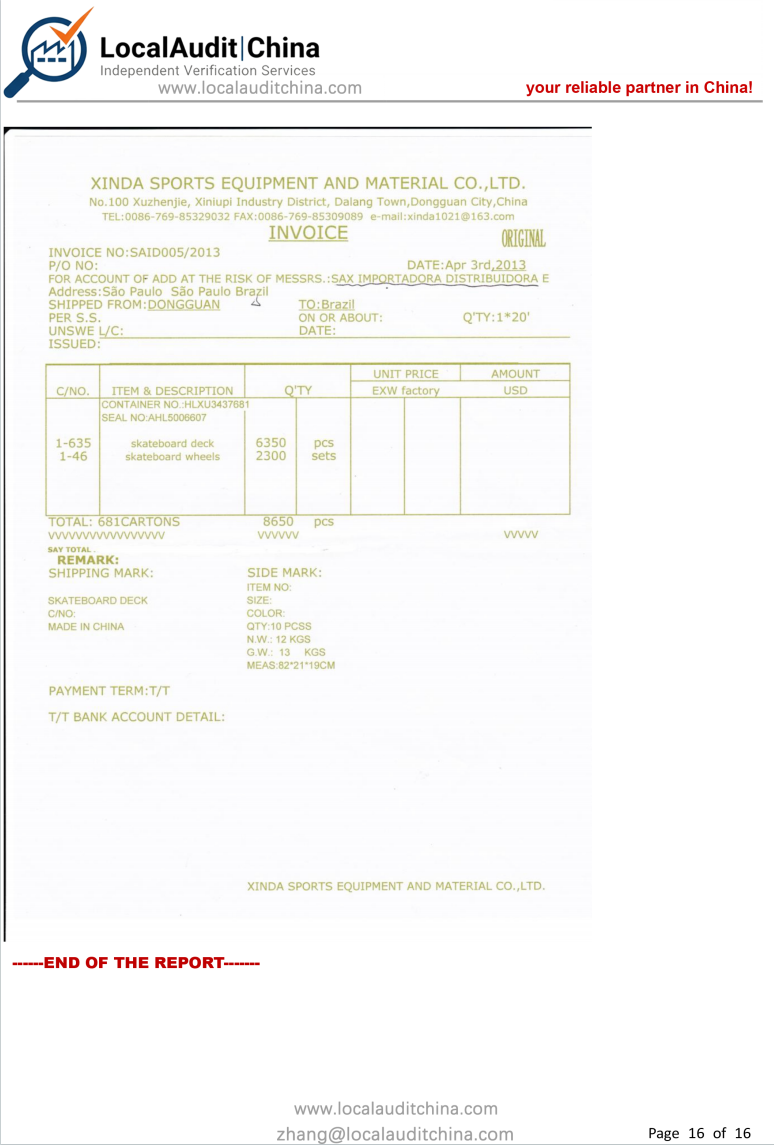

The ultimate proof of a factory’s capability is not just what they say, but what they have actually delivered. The final page of our report provides a "Live Transactional Snapshot" to prove the factory's active status in the global market.

Key highlights from the final page:

Real-World Commercial Invoice: We include a sample invoice from a recent shipment (e.g., to Brazil). This proves the factory is currently operational, exporting goods, and handling international documentation correctly.

Order Specifics Verification: The invoice documents exact quantities (8,650 pcs), descriptions (skateboard decks and wheels), and shipping marks. This confirms they have experience handling large-scale container loads ($1 \times 20'$ container).

Financial Infrastructure: We verify the factory’s payment terms (T/T) and banking details, ensuring you are sending funds to a verified corporate entity.

Auditor’s Final Seal: This marks the end of our 16-page journey, providing a complete, unvarnished truth about your potential partner in China.

Request an On-site Audit / Inquiry